Why Choose Butterfly Valves for Sale in Your Projects?

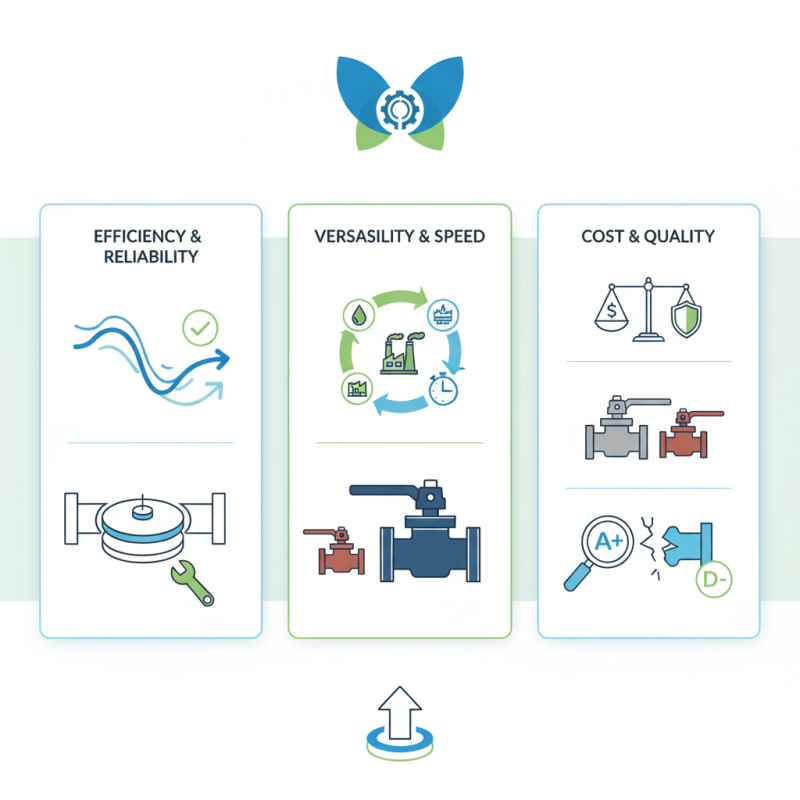

When considering equipment for your projects, butterfly valves for sale stand out for several reasons. These valves are efficient and reliable, making them ideal for various applications. Their compact design allows for easier installation and maintenance. You can find butterfly valves in different sizes and materials, catering to diverse needs, from water supply to industrial processes.

One notable advantage of butterfly valves is their ability to provide quick shutoff. This functionality is crucial in many industries. Additionally, they require less material than traditional valves, which can reduce costs. However, it's essential to ensure you choose quality products. Not all options on the market provide the same level of performance or durability.

Some may overlook the importance of buying from reputable suppliers. This can lead to purchasing subpar valves that may not meet project requirements. Balancing cost and quality is vital in decision-making. In conclusion, exploring butterfly valves for sale can greatly benefit your projects when you take the time to evaluate your options critically.

Benefits of Using Butterfly Valves in Industrial Applications

Butterfly valves are gaining popularity in various industrial applications. They are known for their simple design and efficiency. These valves can regulate flow effectively with minimal pressure drop. Their lightweight construction is also an advantage, making installation easier.

In many scenarios, butterfly valves demonstrate their versatility. They can handle different media, including water, oil, and gas. This adaptability is crucial in industries like water treatment and chemical processing. However, some may overlook potential wear over time. Regular maintenance is needed to ensure optimal performance. The sealing capabilities can degrade, especially in corrosive environments.

Cost-effectiveness is another appealing aspect. Butterfly valves typically require less material than other valve types. This leads to lower manufacturing costs. However, the initial purchase price might not always reflect long-term value. Investing in quality components is essential to avoid frequent replacements. Ultimately, choosing butterfly valves can be beneficial if the specific requirements are met.

Key Features of Butterfly Valves that Enhance Project Efficiency

Butterfly valves are increasingly favored in various projects due to their unique features. Their compact design allows for easier installation in tight spaces, which can significantly reduce overhead costs. Often, they are lighter than other valve types, making handling simpler and more efficient. However, this lightweight design can sometimes lead to installation errors if not managed carefully.

A key feature of butterfly valves is their quick operation. They can be opened or closed with a simple quarter turn. This rapid action can enhance workflow and reduce downtime. Additionally, they provide excellent flow regulation, which is crucial in many applications. That said, the sealing performance can vary based on the materials used. It’s essential to select the right material for specific conditions to avoid leaks over time.

The durability of butterfly valves makes them appealing too. They can withstand high pressure and temperature, depending on their construction. Yet, this durability is not universal. Some models may not hold up as well in corrosive environments. Regular maintenance is crucial to ensure longevity. Ignoring this can lead to unexpected failures or inefficiencies.

Comparison of Butterfly Valves with Other Valve Types

When selecting valves for various projects, butterfly valves stand out. They offer unique advantages over other valve types, especially in terms of space and efficiency. Unlike gate valves that require more space, butterfly valves have a compact design. This design allows them to handle larger flow rates with minimal pressure loss.

In contrast, ball valves provide a tight seal but can be bulky for certain applications. On the other hand, the operational mechanism of butterfly valves is simple. They use a rotating disc to control flow, leading to reduced wear over time. This simplicity can save time and maintenance costs.

**Tips:** Consider the size and space when choosing your valves. Butterfly valves may be best in tight spaces. Always evaluate the flow requirements for your project to find the right balance between performance and cost.

Keep in mind that while butterfly valves are efficient, they may not suit every application. Their performance can vary under high-pressure situations. Understanding these limitations is crucial for making informed decisions.

Why Choose Butterfly Valves for Sale in Your Projects? - Comparison of Butterfly Valves with Other Valve Types

| Valve Type | Flow Control | Pressure Rating | Cost Effectiveness | Installation Space | Maintenance Requirement |

|---|---|---|---|---|---|

| Butterfly Valve | Excellent | 150 psi | High | Compact | Low |

| Gate Valve | Good | 200 psi | Medium | Standard | Moderate |

| Ball Valve | Excellent | 300 psi | High | Standard | Moderate |

| Check Valve | Good | 150 psi | Medium | Standard | Low |

Factors to Consider When Selecting Butterfly Valves for Your Project

When selecting butterfly valves for your project, several factors come into play. The size of the valve matters greatly. It should fit the piping system perfectly. An ill-fitting valve can lead to leaks or flow issues. Material choice is also crucial. Different environments require different materials. Ensure you choose materials that resist corrosion and wear.

Another essential consideration is the pressure rating of the valve. Not all valves can handle high pressures. Operating conditions should guide your selection. Also, think about the actuator type. Manual and automatic options exist. Each has its pros and cons. Automatic actuators offer speed, while manual ones provide better control.

Maintenance requirements should not be overlooked. Some butterfly valves may require frequent checks and replacements. Understand the lifecycle costs as well. Products with lower upfront costs might not always be the best choice. Factor in durability and efficiency to avoid surprises later on. Balancing these elements can be challenging, but it leads to better project outcomes.

Butterfly Valves Selection Factors

Maintenance and Longevity of Butterfly Valves in Operational Settings

When considering operational efficiency, maintenance and longevity of butterfly valves are crucial. Studies show that effective maintenance can extend a valve's lifespan by 30% or more. Regular inspections help identify wear patterns. Corrosion is a common issue. If not addressed, it can reduce a valve’s performance significantly.

In many industrial settings, the operational environment affects valve integrity. High temperatures and pressures can accelerate degradation. According to industry reports, valve replacements can cost up to 50% more than regular maintenance over five years. Many facilities neglect this aspect, leading to premature failure. Data indicates that proper upkeep often prolongs service life to over 20 years.

Visual inspection is vital. Simple checks can catch issues early. However, some maintenance crews overlook this, leading to larger problems. Operational downtime can be costly. Ensuring butterfly valves are maintained properly is essential for efficiency and longevity. The balance between cost and performance is delicate, yet when done right, the benefits are clear.